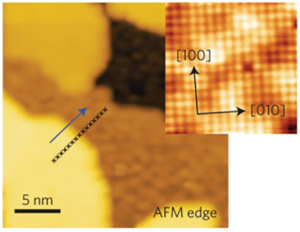

A University of Michigan research team has developed the first reliable, scalable method for growing single layers of hexagonal boron nitride on graphene.

The process can produce large sheets of high-quality hBN with the widely used molecular-beam epitaxy process.

Graphene-hBN structures can power LEDs that generate deep-UV light, which is impossible in today’s LEDs, said Zetian Mi, U-M professor of electrical engineering and computer science and a corresponding author of the study. Deep-UV LEDs could drive smaller size and greater efficiency in a variety of devices including lasers and air purifiers.

Hexagonal boron nitride is the world’s thinnest insulator while graphene is the thinnest of a class of materials called semimetals, which have highly malleable electrical properties and are important for their role in computers and other electronics.

Bonding hBN and graphene together in smooth, single-atom-thick layers unleashes a treasure trove of exotic properties. In addition to deep-UV LEDs, graphene-hBN structures could enable quantum computing devices, smaller and more efficient electronics and optoelectronics and a variety of other applications.

Because graphene and hBN are so thin, they can be used to build electronic devices that are much smaller and more energy-efficient than those available today. Layered structures of hBN and graphene can also exhibit exotic properties that could store information in quantum computing devices, like the ability to switch from a conductor to an insulator or support unusual electron spins.

While researchers have tried in the past to synthesize thin layers of hBN using methods like sputtering and chemical vapor deposition, they struggled to get the even, precisely ordered layers of atoms that are needed to bond correctly with the graphene layer.

The work has been published in Advanced Materials.