This groundbreaking research demonstrates the successful implementation of quantum dots in a natural Si/SiGe heterostructure fully fabricated through an industrial 300mm semiconductor wafer process line. The work represents a significant advancement in silicon-based quantum computing, addressing the challenge of scaling up to the thousands or millions of coherently coupled qubits needed for a universal quantum computer.

The researchers have achieved impressive technical metrics including charge noise values below 2 μeV, spin relaxation times exceeding 1 second, coherence times of T₂* = 1 μs and T₂ = 50 μs in quantum wells using natural silicon, Rabi frequencies up to 5 MHz, and single qubit gate fidelities above 99%.

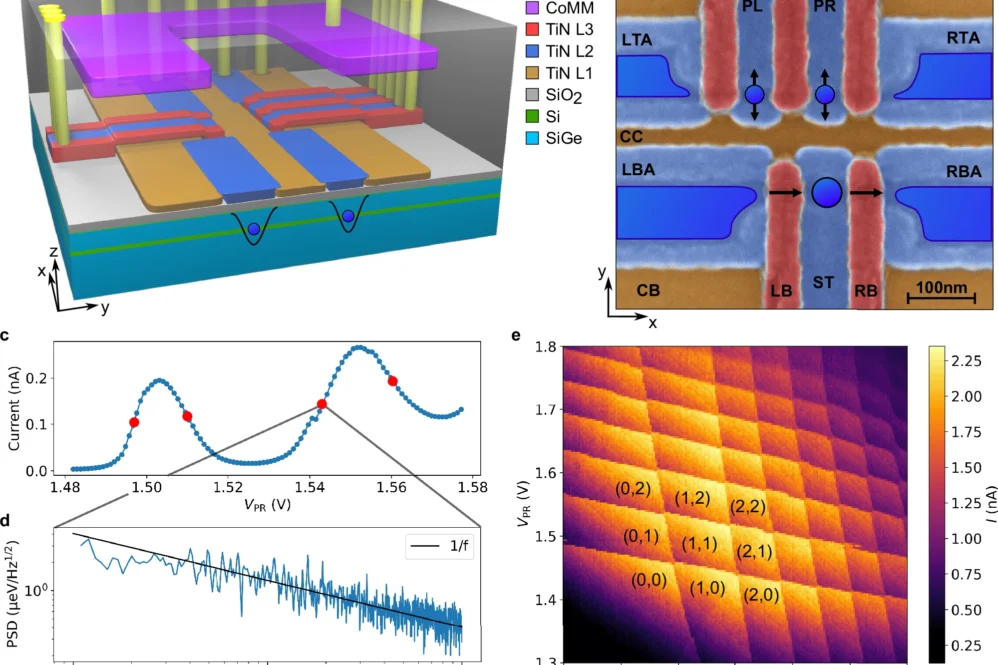

This approach leverages existing semiconductor fabrication infrastructure, enabling both scalability and unprecedented reproducibility. The industrial 300mm processes allow for deterministic study of how process parameters affect qubit performance, which is essential for optimization. While previous quantum processors have demonstrated high-fidelity operations in Si/SiGe heterostructures, this work marks the first fully industrialized fabrication process that incorporates micromagnet control modules through monolithic integration.

The significance of this research lies in its potential to bridge the gap between advanced semiconductor manufacturing capabilities and quantum computing requirements. By solving integration challenges and demonstrating high performance in industrially fabricated quantum dots, this work establishes a viable pathway toward larger-scale quantum processors using existing manufacturing infrastructure and techniques.

The Si/SiGe heterostructure is particularly valuable as it decouples the quantum well from the defective semiconductor oxide interface, which is typically the main source of charge noise. Combined with integrated cobalt micromagnets that enable qubit manipulation through electric dipole spin resonance, the system achieves both high performance and industrial manufacturability.

This research builds upon previous demonstrations of semiconductor-based quantum processors, including the largest reported system of six qubits hosted in an isotopically purified silicon quantum well. However, unlike earlier implementations, this work fully integrates the micromagnet control module into the industrial process flow, addressing a critical barrier to scaling. The high reproducibility of the 300mm processes represents a significant step toward the realization of a universal quantum computer based on silicon spin qubits.

Reference: Koch, T., Godfrin, C., Adam, V. et al. Industrial 300 mm wafer processed spin qubits in natural silicon/silicon-germanium. npj Quantum Inf 11, 59 (2025); doi:10.1038/s41534-025-01016-x