A research team at NUST MISIS, Russian Quantum Center and the Karlsruhe Institute of Technology, has created a quantum sensor that grants access to measurement and manipulation of individual two-level defects in qubits.

A leading qubit technology today is superconducting qubits based on the Josephson junction. That is the kind of qubit IBM and Google use in their quantum processors.

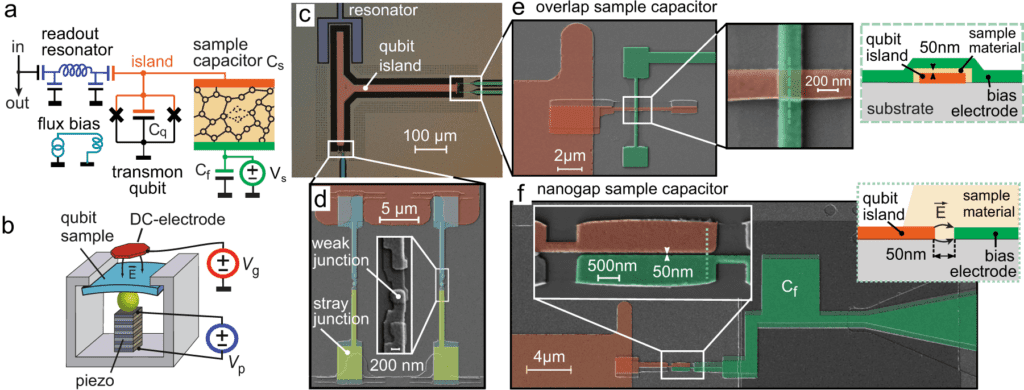

The key element of a superconducting qubit is the nanoscale superconductor-insulator-supercondutor Josephson junction. A Josephson junction is a tunnel junction made of two pieces of superconducting metal separated by a very thin insulating barrier. The most commonly used insulator is aluminum oxide.

Modern techniques do not allow to build a qubit with 100% precision, resulting in so-called tunneling two-level defects that limit the performance of superconducting quantum devices and cause computational errors. Those defects contribute to a qubit’s extremely short life span, or decoherence.

This new quantum sensor grants access to measurement and manipulation of individual two-level defects in quantum systems. The sensor itself is a superconducting qubit, and it allows the detection and manipulation of individual defects.

Traditional techniques for studying material structure, such as Small-Angle X-ray Scattering (SAXS), are not sensitive enough to spot small individual defects, therefore using those techniques won’t help to build the best qubit. The study may open avenues for quantum material spectroscopy to investigate the structure of tunneling defects and to develop low-loss dielectrics that are urgently required for the advancement of superconducting quantum computers. (Phys.org)

The study has been published in npj Quantum Information.