Nanofabrication techniques for superconducting qubits often suffer from residual contamination in the dielectric interfaces of these devices. This occurs because these techniques rely on resist-based electron-beam or optical lithography masks, which are placed and processed directly on the surface of the same wafer where the thin-film metallic qubit structures are deposited.

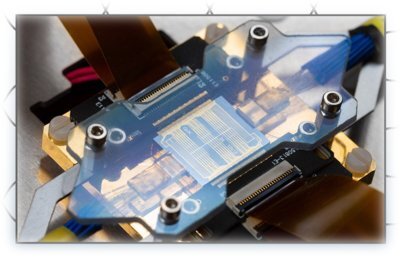

Researchers have developed a technique for making superconducting qubits that minimizes residual contamination and is compatible with high temperature processes. Their technique uses free-standing silicon shadow masks fabricated from silicon-on-insulator wafers, which are separate from the wafers that the qubit metallic layers are deposited on.

Their method involves a type of stencil lithography that naturally separates mask fabrication from device-wafer preparation. This not only minimizes cross-contamination between the mask and the device-wafer, but also makes it possible for researchers to optimize the surface of the device-wafer, without the limitations imposed by standard fabrication techniques.